Vertical Smart Storage

We designed 6 standard modules with the concept of building blocks, and used 6 modules to assemble all customers' needs. Main functions of the equipment

1. Mechanical action

2. Safety protection system

3. Automatic tray height measurement

4. Storage location allocation

5. Manual function

6. System communication

Customers can directly control the vertical smart storage with ERP/MES through our communication specifications.

We use the automatic measuring light curtain to know the height of each pallet, and the PLC program will automatically assign a suitable height to the pallet in progress to effectively use the storage space.

The block design gives the product the characteristics of "easy to dismantle and easy to move". If you want to migrate, it can be directly disassembled it up and down and move the module to reassemble after. Of course, you can also add modules to increase storage capacity to the situation.

Taichung City, Taiwan

Before

1.Using traditional opening shelf storage.

2.Low factory space utilization rate.

3.Opening shelf storage not conducive for easy goods management.

4.Reoccurring issue of material count discrepancies.

5.Similar outlooks of the semi-finished products leads to frequent human errors.

After

1.The introduction of STE Smart Storage results in 50% saving in factory space requirement.

2.Enclosed storage and operator authority setting functions achieve full control in goods management.

3.Storage system drives the real-time inventory information update to eliminate inventory count discrepancy problems.

4.Operator errors minimized by “goods location indicator & QR code identify” functions.

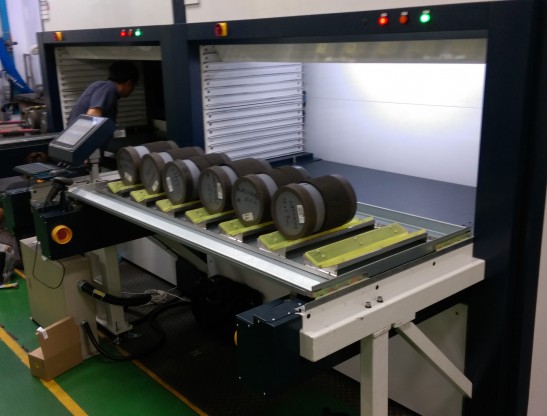

Kaohsiung City, Taiwan

Before

1.Difficulty to control the parts stored in traditional opening shelves.

2.Storing and retrieving by human that waste time.

3.Using traditional opening shelf storage caused low factory space utilization rate.

4.The existing shelves are open space, and materials cannot be effectively managed.

5.Regular occurrence in material count discrepancies.

6.Frequent human errors in material search and the associated costs.

After

1.Goods are managed by smart storage makes the process rapid.

2.By measuring the goods height automatically makes high space utilization rate.

3.Embedded storage and authority setting function resulting in fully secured goods management.

4.Real-time inventory information update in solving material count problem.

5.Tray storage managed by system and with the help by location indicator that eliminate all the mistake chances .

6.Smart storage system connect to the host ERP program makes the higher efficiency .

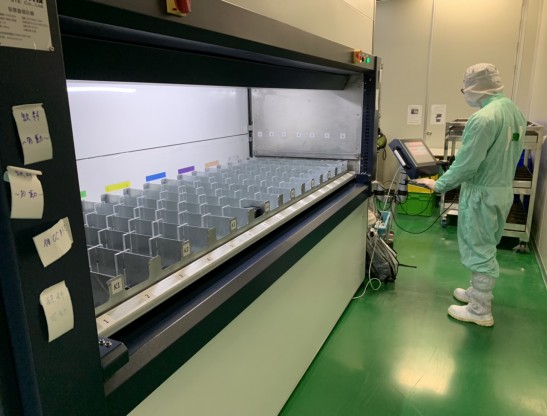

Hsinchu City, Taiwan

Before

1.The wafer cylinders were placed on the pallets in opening space.

2.Time-consuming in searching for materials.

3.Frequent human errors in material search and the associated costs.

4.Traditional open storage resulting in low space utilization rate.

5.Difficulty in handling materials due to the open and uncontrolled space.

6.Regular occurrence in material count discrepancies.

After

1.The company adopted 4 vertical smart storage solutions for storing all wafer cylinders.

2.Greatly improved productivity efficiency due to automatic goods delivery.

3.Human errors minimized in material selection.

4.Vertical goods storage improves the floor utilization rate.

5.Embedded storage and authority setting function resulting in fully secured goods management.

6.Real-time inventory information update in solving material count problem.