Company introductionhttp://www.tm-robot.com

Business item(s)

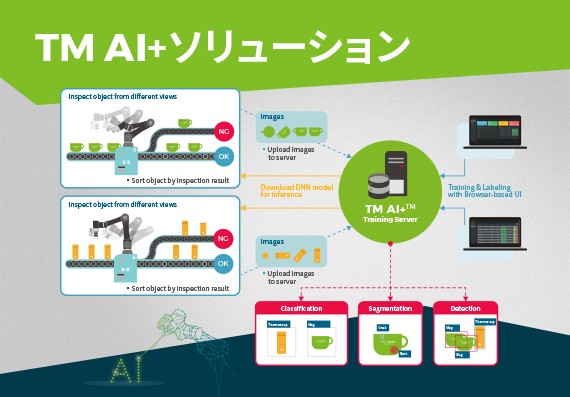

TM AI+ solution

TM AI + is the industry’s first integration of traditional machine and advanced AI vision in a single robotic system. Without the need for additional controllers, time and money required in past integration have been considerably reduced. The built-in machine vision of TM Robots integrates with light, industrial cameras and sensing elements to capture images. The deep learning technology of AI is also combined in order to accurately sense the shape, type and color of an object as a means to further enhance the inspection efficiency and difficulty in automated production, improving the quality inspection and accuracy in different industries. The inspection data is also used as a guide in manufacturing - a step towards digital transformation.

TM 3DVision

The Evolution of Machine Vision A Plug&Use 3D Vision Solution ; No Integrating Efforts Needed Product Features ▪Pre-integrated into TM Robot′s vision system ▪All 3D vision functions, controls, and visual task deployment can be completed in TMflowTM, no need to install or learn new software ▪No external vision controller necessary ▪Two types of compatible 3D camera for users to choose from

TM Palletizing Operator

Product feature: A ready to use, all-in-one application based robot cell: Speed: Up to 7 boxes/min Lifting Pillar: Max. Stack Height 1900mm Adjustable flexible gripper Maximum Payload: 10kg Built-in Safety Controller 16 cell level safety functions with 3rd Party certification PL=d according to ISO13849-1 CE, Machine Directive 2006/42/EC, ISO 10218-2(partly completed machinery) with 3rd Party certification PL=d according to ISO13849- Application Based Software TMstudio Palletizing Wizard: Customizable box and pallet size Custom box arrangement and sequence Palletizing simulation and collision detection Software packages for TMflow: Calibration of pillar File generated from TMstudio Palletizing Wizard, and settings for the cell. Flexibility for functional expansion by user Application: Food processing, manufacturing, Logistics & warehouse management

TM Collaborative Robot

Smart Built-in vision system TM Robot is equipped with a built-in vision system, which integrates into both the hardware and software perfectly, whereas traditional add-on vision solutions to robotics are complicated, time consuming and costly to implement. Masters in robot vision Many robot vision functions are already built into our system: pattern matching, object localisation, image enhancement, bar code reading, colour recognition, etc. All these functions have been integrated into our remarkably easy-to-use user interface. 5 Minutes to achieve a visual pick & place task Combining our smart vision system and our hand-guiding functions, everyone, even those without robotic programming experience, can achieve a visual pick & place task within 5 minutes. Simple Revolutionary user interface No more coding! You can implement your TM Robot using our revolutionary simple-to-use interface, an all-graphic flow chart based HMI. Users, even those without coding experience with industrial robots, can learn to use TM Robot easily and quickly. You can program every built-in vision function on the GUI. Furthermore, the traditional heavy umbilical wired pendant is gone. Our user interface can be operated on PCs, notebooks or tablets. Hand-guide functionality Another reason TM Robot is more simple to program than the other modern robots is our well designed hand-guiding functions with servo assist. You can lock selected axes to allow adjustment in defined planes and then fine tune the co-ordinates with easy editing of those co-ordinates within the programming package. Easy to deploy Because TM Robot is so simple to program, it is very easily deployed into different applications, reducing your time-to-production and saving your total cost in automation. Safe Force limiting TM Robot complies with the ISO 10218-1:2011 & ISO/TS 15066:2016 human-robot co-operation safety requirements for collaborative robots, allowing the robot to be programmed with both speed and force limits. Safety is our priority TM Robot is serious about safety in every aspect of the design of the whole robot system, through hardware, software and operational design. Ergonomic design TM Robots are physically designed to be safe to their surroundings, soft end caps and no sharp edges are all part of the collaborative experience.