Company introductionhttps://www.li-ming.com/

Business item(s)

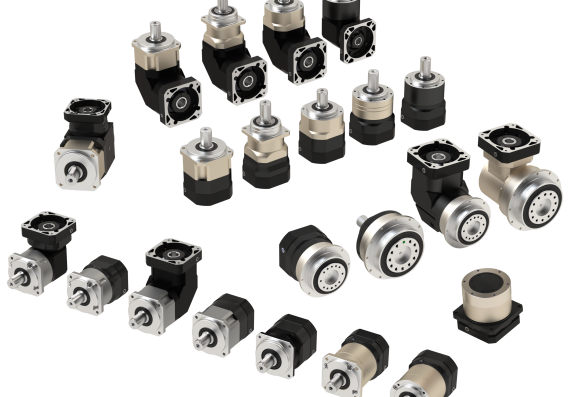

LI MING PRECISION PLANETARY REDUCER

The precision planetary reducer of the SERVOBOX series features a helical gear design, manufactured using high-precision CNC gear hobbing machines. It offers accurate meshing, smooth operation, and low noise. The integrated gearbox housing is compact compared to reducers of the same specification, yet delivers high output torque and excellent transmission efficiency. Application Fields: Smart Factory, Metal Processing, Aerospace, Medical, Energy, Transportation, Rubber & Plastics, Shoe Manufacturing, Textile, Electric Vehicles, Semiconductor, Food Processing, Packaging

STRAIN WAVE GEARING REDUCER

The Strain Wave Gearing Reducer (also known as a harmonic drive reducer) is a high-precision reduction device designed based on the principles of metal elasticity, main advantages: Zero Backlash, High Reduction Ratio,High Torque Output, Lightweight and Space-Saving, Quiet Operation and Low Vibration, High Positioning Accuracy and Repeatability, Perfect for robotics and precision automation equipment.

CYCLOIDAL REDUCER

A Cycloidal Reducer is a type of speed reducer that utilizes a cycloidal pin-wheel transmission mechanism. It combines the involute cylindrical gear planetary reducer structure with the cycloidal pin-wheel planetary reducer mechanism. The crankshaft drives the cycloidal disc to perform an eccentric motion, achieving efficient speed reduction. Its core components include the needle gear housing, crankshaft, and cycloidal disc.

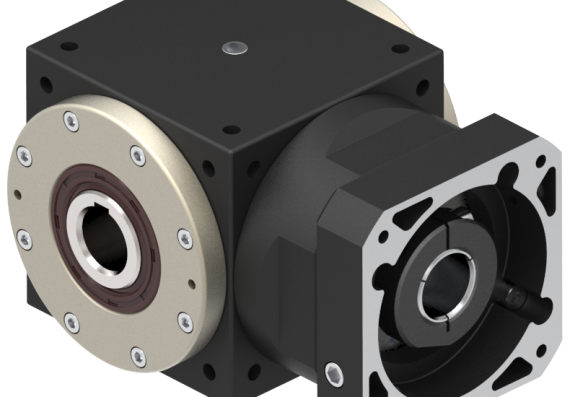

SPIRAL BEVEL GEAR REDUCER

A Spiral Bevel Gear Reducer is a mechanical device that uses spiral bevel gears for power transmission and speed reduction, widely used in industrial applications requiring right-angle transmission, high efficiency, and high torque, and flexible installation, spiral bevel gear reducers are essential components in industrial transmission systems.

YPOID GEAR REDUCER

A HYPOID GEAR REDUCER is a type of speed reducer that uses hypoid gears, which are similar to spiral bevel gears but with the input and output shafts offset and not intersecting. This unique structure allows for higher reduction ratios, increased load capacity, and reduced operating noise.