Company introductionwww.tai-wa.com.tw

Business item(s)

Custom Acrylic Sneeze Guard

Name: Acrylic barrier sneeze guard Application: Bank Counter, Conference Room, Hot Pot Restaurant, School Cafeteria, Freeway Service Area, Yakiniku, Cafe Board thickness: 1.2-2mm Material: SUS hair line/ Acrylic Processing: Laser cutting- Laser engraving-Tapping-Bending-Welding

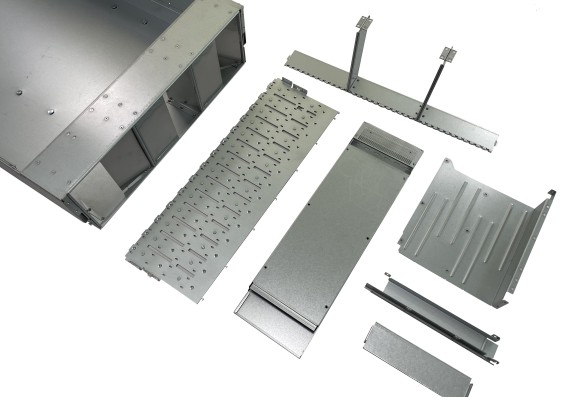

Precise Electric Control Box

Name: OEM surface treatment electric metal case Application: Industrial machinery, electric control box Board thickness: 0.5-5mm Material: SPCC / SUS / SECC / Aluminum / SGCC / Copper Processing: Laser cutting-Tapping-Bending-Welding-Grinding-Surface treatment

OEM Sheet Metal Fabrication

Name: Application: OEM/ODM sheet metal fabrication parts Application: Medical, industrial machinery, optoelectronics industry, LCD screen panel, food machinery, automation machine covers, aerospace, semiconductor and dust-free room equipment. Board thickness: 0.5mm-25mm Material: SPCC/SUS/SECC/Aluminum/SGCC/Copper Processing: Laser cutting-Tapping-Bending-Welding-Grinding-Polishing-Surface treatment

Automation Industrial Machinery

Name: Customized metal aesthetic design for machinery enclosure Application:Medical, industrial machinery, optoelectronics industry, LCD screen panel, food machinery, automation machine covers, aerospace, semiconductor and dust-free room equipment. Board thickness: 0.5-5mm Material: SPCC / SUS / SECC / Aluminum / SGCC / Copper Processing: Laser cutting-Tapping-Bending-Welding-Grinding-Surface treatment