MCTC Automatic Tool Changer

MINDMAN www.mindman.com.tw Tel: +886-2-25914100

● World's First Innovative Concept

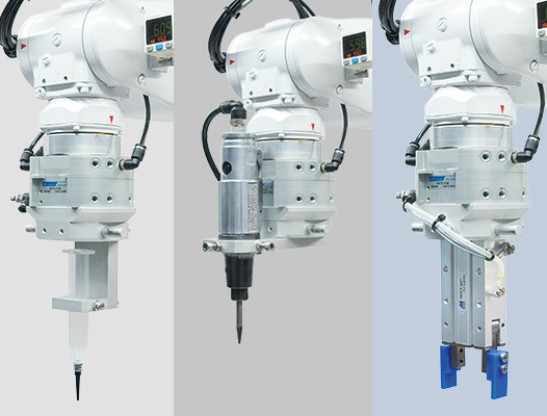

The "MCTC Quick Tool Changer" consists of an R-side module and a T-side module. The R-side module can be mounted on various types of robotic arms, while the T-side module is equipped with tools based on different operational requirements, such as grippers, pneumatic tools, vacuum suction cups, and more. A single R-side module can correspond to multiple T-side modules, greatly enhancing production flexibility and saving changeover time and labor costs.

Most competing products adopt a protruding-type locking mechanism on the R-side and a fixed ring on the T-side, which involves complex machining processes. Additionally, when wear occurs in the structure, the entire unit must be replaced. The uniqueness of our product lies in the R-side module’s flat taper hole locking mechanism and the T-side module’s pull stud. Driven by air pressure, the R and T modules are joined using a taper-fit mechanism, enabling automatic alignment upon connection.

For example, under a rated load of 25 kg, the repeatability reaches ±5 µm—significantly better than the ±15 µm offered by competitors. Furthermore, it can automatically compensate for wear clearance during long-term use. To validate its service life, a test was conducted using 1.5 times the rated load for 3 million cycles, and results showed repeatability remained under ±15 µm—still superior to the ±30 µm repeatability of most robotic arms. This proves that the product not only delivers excellent performance but is also highly reliable in terms of durability and quality.