Zero Defect Quality Culture & Mindset

ZERO DEFECT QUALITY CULTURE & MINDSET! THAT INCLUDES

EVERYONE & WITH EVERYTHING YOU DO

Technology readiness > DFM &DFT

Each Single Defect is Reported & Analyzed

Accept No Compromises

Drive All Decisions with Data

Go Very Deep Into the Technology

Disciplined Change Management

Proactively Seek Problems and Solve Them

Engineering Curiosity & Healthy Paranoia

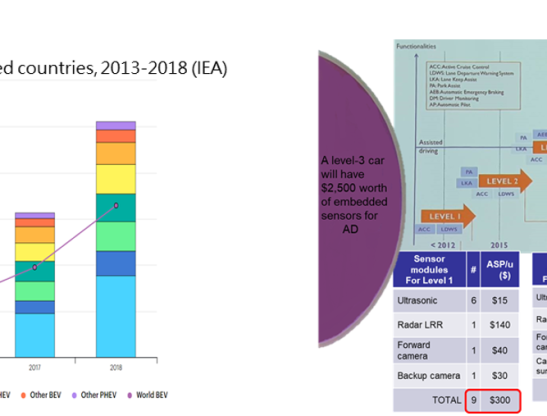

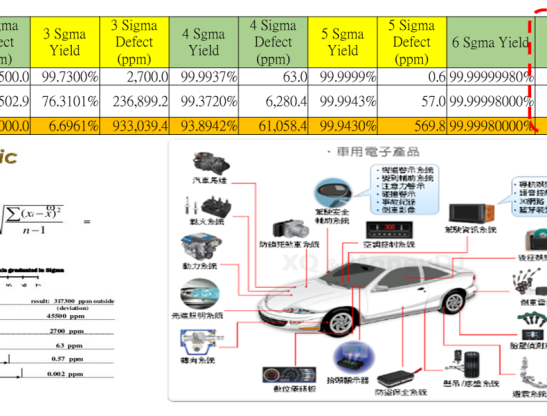

汽車安全是今後的重大問題

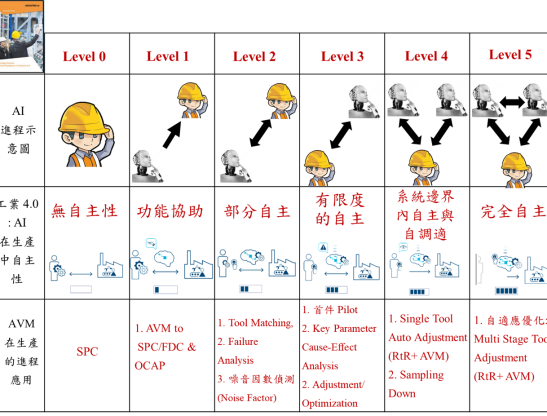

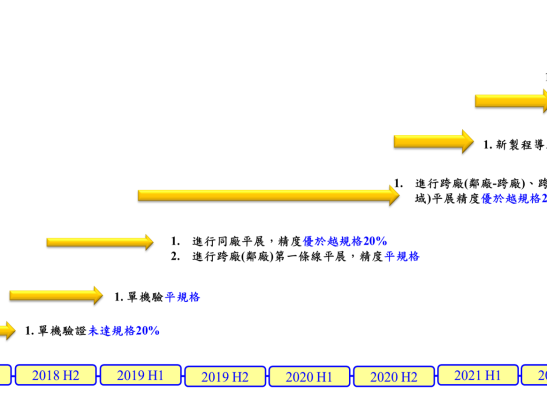

AVM 進程:

L0: SPC

L1: AVM to SPC/FDC: OOC/OOS

L2: AVM:

Tool Matching,

Failure Analysis & 未含異常因子 (Nose Factor Alarm)

首件 Pilot

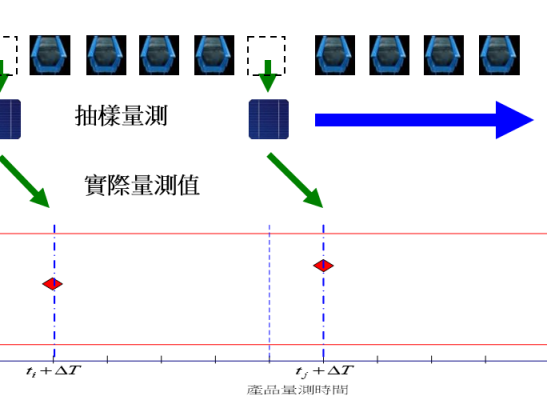

L3 AVM: Sampling Down

L3: Key Parameter Analysis

L4: Manual Tool Adjustment

L4: Single Tool Auto RtR+ AVM

L5: Multi stage Tool RtR+ AVM & Chamber 產能提升最佳化

工商時報 2021/9/27 “群創入選2021世界經濟論壇(WEF)燈塔工廠” 新聞

新聞的效益: 產品最終不良率降低 33%、利基產品比重增加 22%、品質偵查時間降低 90%、總產能增加 10% ; 其中 AVM 都在其中扮演重要角色。