AI NDT Inspection Solution

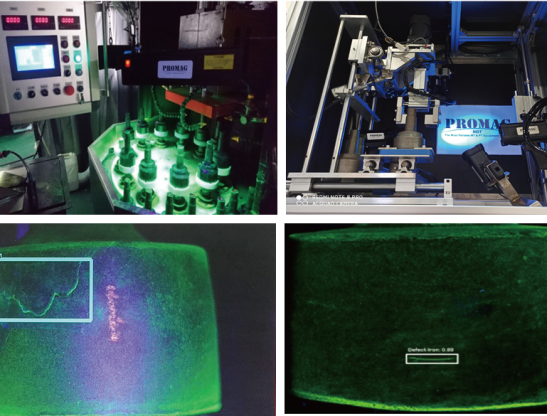

As a leading NDT equipment manufacturer of MPI & FPI solutions, PROMAG has developed and provided AI-based

software robotics to industries across the world, assisting manufacturers to optimize processes of inspection, recognition

and production, and improve cost-effectiveness, labor-efficiency, system automation and inspection reliability.

Overview of Artificial Intelligence NDT (AI NDT)

Artificial Intelligence (AI) is going to become fundamental to the operations of every industry sector-wide. It is a technology that offers great promise not just for business improvements but for human-centric innovation. AI utilizes relevant data to automate and amplify human capabilities, eliminate mundane and repetitive tasks, generate additional revenue streams, and enable unbiased decision-making exactly and faster time to market.

Due to the rapid changes in the external environment of the market and the fiercely competitive manufacturing technology and quality requirements, the NDT market demands have been turning to be looking for a more intelligent, brilliant, efficient, stable, and labor-saving in order to meet this trend.

Benefits of Artificial Intelligence Flaw Detection / Robot Defect Recognition solution

PROMAG specializes in customizing flaw detection equipment known as MPI and FPI in the NDT field. Especially for customer's specific mass production inspection needs. Our team builds the interactive controlled system by the AI deep-learning unit for defect types and the turnkey automated solutions.

Through years of technical development of AI and automation, PROMAG, with the specialty of MPI, FPI, UV-LED, and cleaning system, has engineered an Artificial intelligent NDT(AI NDT) inspection system solution to upgrade the MPI and FPI inspection capacity, the quality of flaw detection, the accuracy and the stability of MPI and FPI system by integrating machine-learning of AI NDT robot software and defects platform, in which the defects data can be not only stored but also automated feedback to the quality assurance department directly in order to have the management in the company understands the situation and make a better decision based on types of true-defects and also make a change in the manufacturing process to reduce the NG/NOK parts' rate effectively.

Applied Industries

Aerospace, Military&Army, Steel, Automotive.

Applied Field

Forging / Pressing / Forming, Metallurgy, Casting, Machining, Heat-treatment, Thirty-party Lab.

智慧探傷非破壞磁檢 / 螢檢探傷系統開發與缺陷辨識技術整合應用

智慧探傷非破壞磁檢 / 螢檢探傷系統開發與缺陷辨識技術整合應用

特別針對現場客製化與量產性之探傷使用客戶,研究開發:

智慧探傷非破壞檢測系統解決方案特點與優勢

現場探傷檢測設備智慧化

物聯網IOT裝置建置與管理

智慧探傷檢測模組效益分析與管理

探傷品質的精度與效率

探傷檢查的省人化與自動化

現場及時支援與服務現場單位

探傷技術與管理表單整合平台

缺陷瑕疵統計分析與學習

回饋生產單位進行製程調整與改造(缺陷原因改善,避免再次發生)