Compact I/O modules reduce hardware requirements as well as costs and cut equipment assembly times in half

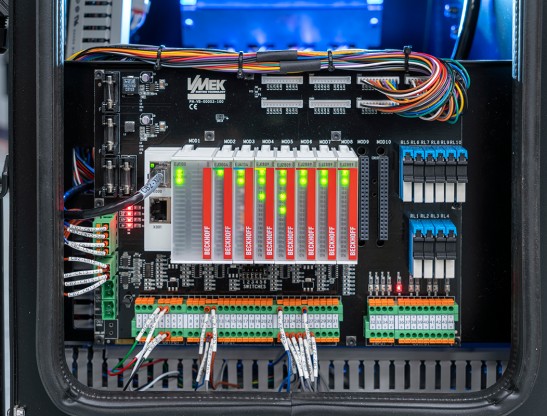

EtherCAT plug-in modules reduce footprint, costs and assembly time. Pluggable EJ series EtherCAT modules. These I/O modules are roughly half the size of standard EtherCAT Terminals, but they provide the same functionality. Together with the JST connectors selected by VMek for this application, they mount directly to custom-designed PCB boards, and the entire signal distribution board connects to the larger PC-based system via prefabricated cables or coded plug connectors. Because the boards come essentially prebuilt, this makes series production more efficient and cost effective compared to traditionally wired terminals.

VMek™ Sorting Technology

The machines, including the Metrix Analytic Lab Color Sorter™ and Element Analytic Production Color Sorter™, leverage new technologies to meet the needs of customers in the agriculture industry, including the top three seed producers in the U.S.

By implementing EJ series EtherCAT I/O modules with standardized signal distribution boards for each sorting machine, VMek was able to cut time to market significantly. “We estimate that we reduced our equipment assembly time by 50%,” Kent Lovvorn says. “We have also minimized service time, if it’s ever needed.” Small adjustments at the hardware level helped VMek cut costs by roughly 700 U.S. dollars per I/O segment, and the company reinvested these savings in R&D to continue to enhance its optical sorting machines and software.