Company introductionwww.icpdas.com

Business item(s)

PMC-5231 IIoT Power Meter Concentrator

PMC-5231 is the new generation of Power Meter Concentrator for meeting the trend of energy saving and carbon reduction in the Industry 4.0 age. It provides flexible integration with the ICP DAS power meters via RS-485 or Ethernet interface, and features various functions such as: measure the power consumption of the devices, energy usage analysis, power demand management and alarm notification functions. The PMC-5231 features a built-in Micro SD card. After it retrieving the power data from the power meter, it will save the power data in data log file, and automatically send back the data log files to the back-end management center for data analysis and statistics. PMC-5231 offers a user-friendly and intuitive web site interface that allows users to implement the Energy monitoring and management system just a few clicks away; no programming is required. In addition to ICP DAS XV-Board and M-7000 I/O modules, the PMC-5231 can also connect to standard Modbus TCP/RTU Slave modules. By working with the I/O modules, and functions such as IF-THEN-ELSE logic rule execution and alarm notification functions including LINE/Email, PMC-5231 offers more thought-out power demand management and alarm notification functions, and is able to perform load shedding of the devices if required, and enables real-time monitoring and control of the power consumption of the devices. PMC-5231 also supports the Modbus TCP/RTU, SNMP, FTP and MQTT protocols for seamless integration with the back-end SCADA/MES/IT/IoT/Network Management systems. So that the administrator can monitor the status of power consumption of each device and perform statistics and analysis of the power information, thus improving the overall efficiency in electricity consumption to save costs on utility bills. All of these features make PMC-5231 a perfect concentrator of power meter in the Energy monitoring and management application of Industry 4.0 age.

PMD-2201 IIoT Power Meter Concentrator with Touch Panel

The PMD-2201 is a web-based intelligent Power Meter Concentrator developed by ICP DAS. It offers webpage interface, and features various functions such as: power data collection, logic control, power demand management, data logger, local display/Web page data display and alarm notification functions. PMD-2201 allows connections to ICP DAS Smart Power Meters via RS-485 or Ethernet interface to read the power data of the devices measured by the power meters; and then real-time record the power values in the data logger file. PMD-2201 also provides data logger file auto send-back function; together with PMC Data Server software or SCADA software, it allows collection and analysis of the power data. PMD-2201 is equipped with the 7" TFT LCD (with Touch Panel) and designed for panel mount installation. It provides an easy way for viewing the power data and setting the system parameters at the local side. In addition, PMD-2201 also is equipped with built-in Web Server that allows direct connections via browsers to the PMD-2201 for viewing power data and setting up the system parameters. PMD-2201 also supports the Modbus TCP/RTU, SNMP, FTP and MQTT protocols for seamless integration with the back-end SCADA/MES/IT/IoT/Network Management systems. In addition to ICP DAS M-7000 I/O modules, the PMD-2201 could connect to standard Modbus TCP/RTU Slave modules. By working with the I/O modules, and functions such as IF-THEN-ELSE logic rule execution and alarm notification functions including LINE/Email, PMD-2201 offers more thought-out power demand management and alarm notification functions, and is able to perform load shedding of the devices if required, and enables real-time monitoring and control of the power consumption of the devices. When using PMD-2201 to build a power management and monitoring system, during the whole process of system development, no programming is required; it takes a few clicks on web page to complete all settings; it is easy for the user to quickly view the power data of the devices and furthermore process the data for statistics and analysis. The PMD-2201 is an easy-to-use and easy-to-build total solution for power management and monitoring that makes more efficient energy usage.

U-7526M OPC UA I/O Modules

OPC UA I/O modules is a series of Ethernet I/O modules that is built-in with the OPC UA Server and MQTT Client services, and supports to run both communications at the same time. The UA I/O supports the OPC UA server and MQTT client communication in industrial networking communication. Users can choose the networking mode or to run both communications at the same time according to their needs and environment. It transmits the values of built-in I/O channels to the cloud IT system or field control system for reading and writing. UA I/O Series provides a Web-based User Interface (Web UI) to configure the module, control the output channels, monitor the connection, and I/O status via a general web browser. It is easy, fast, and no extra APP needed. The new UA I/O Analog modules support Scaling function and it enables the analog signal being converted into an easy-to-read value.

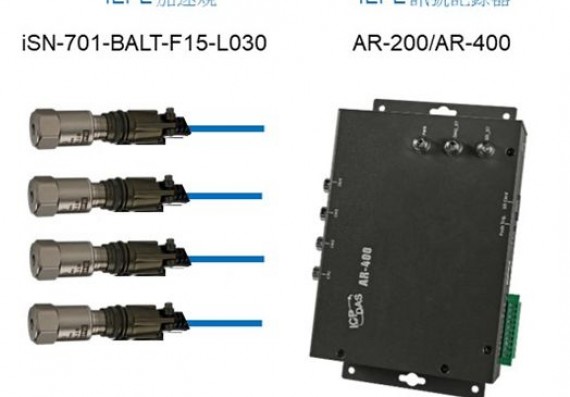

high sensitivity accelerometer

The accelerometer is the most commonly used sensor for vibration measurement.The iSN-701-BALT-F15-L030, iSN-701-BALT-F15-L060 and iSN-703-BALT-F1-L015 are high sensitivity accelerometer for vibration analysis applications. iSN-701-BALT-F15-L030 and iSN-701-BALT-F15-L060 are homotaxial IEPE accelerometer. They are suitable for vibration modules such as AR-200/AR-400,and can also be used with SG-3227 to connect to PET-7H16M. iSN-703-BALT-F1-L015 is a triaxial accelerometer that can simultaneously measure vibration in three orthogonal axes. It can be used with the SG-3037 to connect to the PET-7H16M.

tGW-718-T, tGW-718i-T – Tiny Modbus/TCP to RTU/ASCII Gateway with single (Isolated) RS-232 or 422/485 Port

Modbus has become a de facto standard industrial communication protocol, and is now the most commonly available means of connecting industrial electronic devices. Modbus allows for communication between many devices connected to the same RS-232/422/485 network, for example, a system that measures temperature and humidity and communicates the results to a computer. Modbus is often used to connect a supervisory computer with a remote terminal unit (RTU) in supervisory control and data acquisition (SCADA) systems.Modbus has become a de facto standard industrial communication protocol, and is now the most commonly available means of connecting industrial electronic devices. Modbus allows for communication between many devices connected to the same RS-232/422/485 network, for example, a system that measures temperature and humidity and communicates the results to a computer. Modbus is often used to connect a supervisory computer with a remote terminal unit (RTU) in supervisory control and data acquisition (SCADA) systems. The tGW-718(i)-T module is a Modbus TCP to RTU/ASCII gateway that enables a Modbus/TCP host to communicate with serial Modbus RTU/ASCII devices through an Ethernet network, and eliminates the cable length limitation of legacy serial communication devices. The module can be used to create a pair-connection application (as well as serial-bridge or serial-tunnel application), and can then route data over TCP/IP between two serial Modbus RTU/ASCII devices, which is useful when connecting mainframe computers, servers or other serial devices that use Modbus RTU/ASCII protocols yet themselves do not have Ethernet capability. The tGW-718i-T also adds 3000 VDC isolation and +/-4 kV ESD protection component that diverts the potentially damaging charge away from sensitive circuit to protects the module and equipment from the sudden or momentary electric current.

DL-1038 PM1/PM2.5/PM10/CO/CO2/TVOC/Temperature/Humidity/Dew Point Data Logger Module

The DL-1000 is a series of particle and gas measurement module that can measure the concentration of aerosols such as PM1, PM2.5, PM10 and the number of particles (0.3μm, 0.5μm, 1μm, 2.5μm, 5μm, 10μm) in the air. In addition, a variety of fume concentrations, such as CO/CO2/TVOC which may be harmful to human health can also be measured. DL-1000 can trigger an alarm when the concentration is too high. It can be used to record PM1/2.5/10, CO, CO2, TVOC, temperature, humidity and dew point data, including date and time stamps, and is able to store up to 180,000 downloadable records. Real-time data can be accessed from the DL-1000 series Data Logger from anywhere and at any time by using the free Windows software, the iOS App or the Android App, as long as it is connected to the same local network as the Data Logger being connected to. Popular industrial protocols such as DCON, Modbus RTU, and Modbus TCP, as well as the emerging machine-to-machine (M2M)/IoT (Internet of Things) connectivity protocol - MQTT are supported. The DL-1000 series Data Logger can be connected via widely used communication interfaces including RS-485, Ethernet and PoE, meaning that the device can be easily integrated into existing HMI or SCADA systems, and is easy to be maintained in a distributed control system. The DL-1000 series provides IP43 grade protection approval and is designed for industrial applications in harsh environments . The rugged RJ-45 ensures tight, robust connections, and guarantees reliable operation, even for applications that are subject to high vibration and shock.