Company introductionwww.tirc.com.tw

Business item(s)

Outdoor Inspection Robot

Power company recognized the need for monitoring power equipment temperature as an effective way to prevent accidents at electrical substations and power grids. Maintaining trained staff to regularly and safely audit all necessary equipment is costly and the location of unmanned substations are often located in remote area where getting there will take a long time. The substation inspection robot is created with heavy-duty complex terrain outdoor mobile platform to patrol substation facilities’ while avoiding obstacles. It has smart inspection to navigate through substation and perform infrared thermal image scanning of the area’s power equipment with the robot’s embedded robust pan-tilt positioner to conduct remote monitoring that scan for temperature differences, identify hot spots problem area, perform sound recording, diagnose the issues, and send abnormal alarm notification when a problem is identified. Stationing a substation inspection robot at unmanned electrical substations is an effective way of lowering cost and to prevent accidents at electrical substations and power grids.

Bubble Tea Shaker Robot

The Bubble Tea Shaker Robot (BTSR) is a highly integrated bubble tea beverage store which takes order via app, accepts payment, makes individual customized bubble tea, attaches the printed label to the cup and waits for customer pick up. The BTSR sets itself apart by removing the on-site waiting time, the potential for preparation error and the unexpected variability, setting a new standard for automation technology in the specialty bubble tea service industry. The tirc has integrated more than 10 stations and created mechanical, software and firmware systems that are highly modularized, easily serviced, easily assembled and also cost-effective.

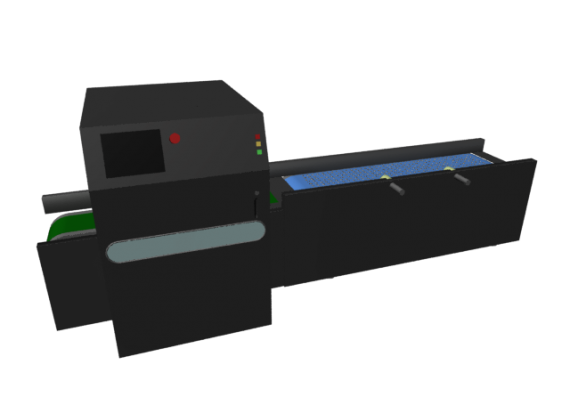

On Demand Color Injet Printing System

Large-scale logistics company often undertake the final goods packaging for several e-commerce companies at the same location. Managing different specifications of box materials can be a nightmare. It consumes a lot of manpower and takes up a lot of storage space. This machine combines a steering and side-rear universal ball conveyor belt with a multi-module serial vertical color inkjet printer that autonomously align the four-color printing for various different sizes of boxes with a high speed continuous CMYK printing speed of 29m / mins. It can quickly complete the specified logo printing on the picking line addressing the needs for different customers, and saves the bottom line.

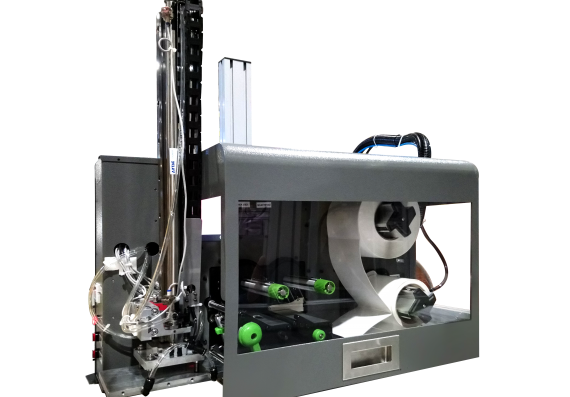

On Demand Auto Labeling System

Our automated print and apply labeling systems are proven to increase distribution efficiency in both existing and new order fulfillment operations. The systems are scalable and flexible to auto apply the widest array of label sizes and types, saving time and money across manufacturing and distribution applications. Eliminate bottlenecks throughout your distribution center by eliminating manual labeling processes with high performance, reliable print and apply labeling systems.

Bio Array Analyzer

tirc’s biomedical customer is currently one of only three companies in the world that can produce high-density genetic chips, headquartered in California, USA. The company’s new-generation microarray chip has the advantages of high density and high quality. This genetic testing technology can be applied to early tumor screening, pathogen detection, preventive medicine, and health management and other testing services. The respiratory virus detection chip can simultaneously perform sequence analysis on more than 60 viruses, including the new coronavirus, to achieve accurate detection of new coronavirus and other common respiratory pathogens; in addition, the whole genome chip can analyze nearly 1 million human disease-related genes, such as cancer, genetic diseases, metabolism or drug resistance, etc. tirc was commissioned to design, develop and manufactured the high-throughput Bio Array Analyzer, using the conversion of multiple optical lens groups, switches various optical systems of different fluorescent wavelengths, and adds precise optical path adjustment to achieve the effect of uniform light. With this optical system, the information can be read in the chip array, and the entire inspection can be automated through a sophisticated optical mechanism. Up to 384 specimens can be scanned and analyzed at a time. The image of each set of chips is obtained through precise micro control, can accurately focus, obtain high-definition images for detection and analysis.

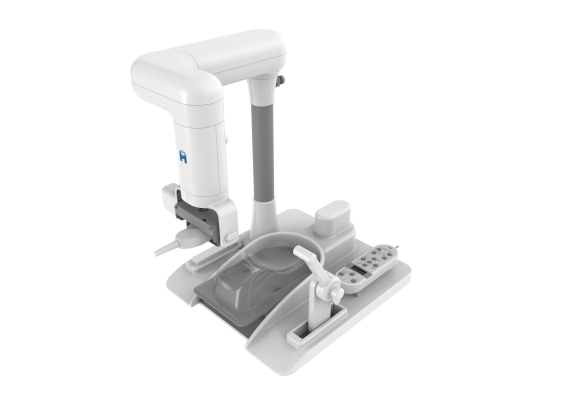

Laser-Guided Positioning &Automated Scanning Analyzer

AmCAD-UO offers 10-minute detection for obstructive sleep apnea on awake patients, helping doctors to evaluate the root cause of sleep apnea and offer assessment for moderate/severe OSA patients. With laser-guided positioning, AmCAD-UO can precisely scan upper airway and analyze the gap between normal breathing and Müller Maneuver models. tirc is commissioned to design, develop and manufacture the Laser-Guided Positioning and Automated Scanning instrument, which is an innovative solution to assist physicians evaluating the risk of Obstructive Sleep Apnea (OSA) syndrome with minimal needs for hands-on training. The instrument can standardize ultrasound transducer scanning to reduce intra-observer variations and make the assessment consistent.