Business item(s)

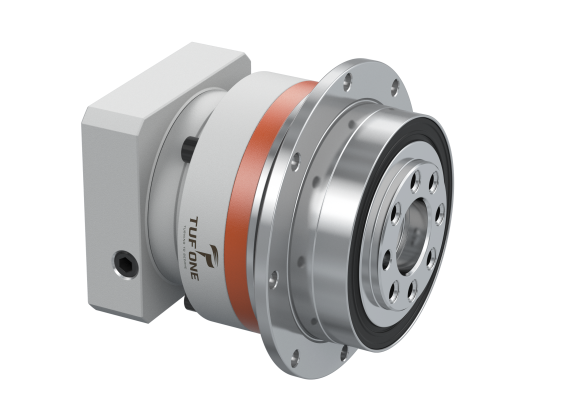

TUH

The TUH Series of high-load precision planetary gear reducers, launched in 2024, is designed for applications requiring precise positioning, such as machine tools and automation systems. Its unique design and exceptional manufacturing capabilities ensure that each gear rotation achieves precise positioning. This maximizes mechanical smoothness and enables high torque output and efficiency during rotation, resulting in highly stable performance under load and enhanced cost competitiveness.

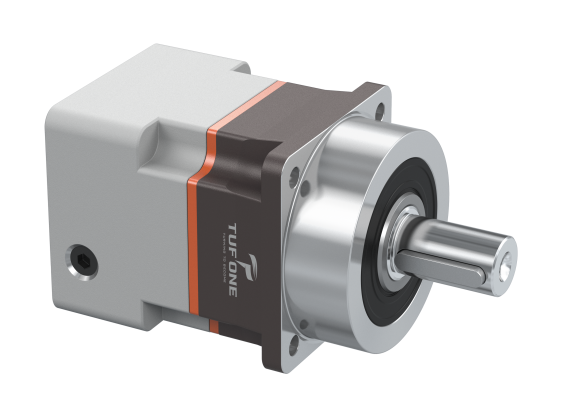

TUB

TUB is designed for equipment with repetitive positioning precision requirements and widely used in applications such as machining machinery, laser engraving machines, and semiconductor production lines. Affordable、Accurate、Versatility. Its output shaft can be selected with a key according to the requirements, making it versatile and flexible for using in various mechanical and equipment applications. TUB is designed to meet industry standard specifications to ensure the compatibility without concerning about fitting issues. TUB's helical gear is designed significantly to enhance the durability and efficiency of gear operation. This is achieved through our precised gear processing technology and unique tooth surface heat treatment, which greatly improve the abrasion resistance and smooth meshing of the gears. The operating noise is controlled within 60 decibels (for frame sizes below 90mm), making it perfectly suited for the commercial environments such as unmanned hotels, restaurants, and more. TUB offers a wide range of ratios from 3 to 100, nearly meeting 99% of equipment deceleration needs. Its maximum output torque reaches up to 1,500Nm, easily handling applications with heavy load requirements and helping you achieve high efficiency, high precision, and stable mechanical operations. The one stage models (ratios 3–10) achieves an efficiency of up to 97%, while the two stage models (ratios 12–100) achieve 94% efficiency. TUB is an economically efficient and widely applicable planetary gearbox. Each input and output interface is designed for easy integration with various additional components. This product provides outstanding performance, flexible installation options, and unparalleled operational flexibility, allowing you to experience convenience and efficiency. * International Protection Marking, IEC 60529. IP65

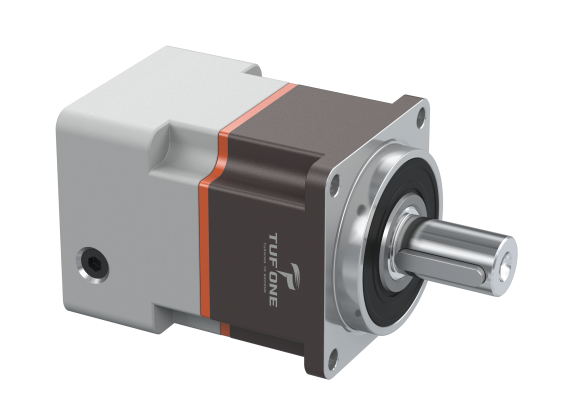

TUF

TUF is designed with Taper roller bearings to handle greater axial and radial forces. Minimizing loss、Advance、Smooth. With high precision positioning, TUF is specifically designed for equipment requiring repetitive positioning, and widely used in applications such as machining machinery and semiconductor production lines. The output shaft can be selected with a key according to requirements, making it versatile and flexible for using in various mechanical and equipment setups. TUF is designed to align with market standard specifications, which eliminatis compatibility concerns. TUF's helical gear design greatly enhances the durability and efficiency of gear operation. This is achieved through our advanced gear processing technology and unique tooth surface heat treatment, significantly improving gear wear resistance and smooth meshing. TUF offers a wide range of ratios from 3 to 100, meeting nearly 99% of deceleration requirements for equipment. Its maximum output torque reaches up to 1,500Nm, easily handling applications with heavy load demands, helping you achieve high efficiency, high precision, and stable mechanical operation. One stage models (reduction ratios 3–10) achieves up to 97% efficiency, while two stage models (reduction ratios 12–100) achieves up to 94% efficiency. * International Protection Marking, IEC 60529. IP65

TUE

TUE is specifically designed for medium level positioning accuracy requirements, offering outstanding performance that makes the entire system exceptionally compact with the competitive price, while providing power transmission efficiency far beyond industry standards. The design of TUE can maximize acceleration, significantly enhancing production efficiency. It allows the equipment to withstand greater loads and operational intensities, meeting the demands of more advanced industrial applications. Its compact design effectively saves equipment space, or rather, precious installation space, enabling easy application in narrower environments, providing users with greater flexibility and convenience. * International Protection Marking, IEC 60529. IP65