Company introductionhttps://cinglian.com.tw

Business item(s)

Customized Resume system

1. The resume platform is a platform for information collection and information feedback on the manufacturing process of products or personal documents. 2. In the industrial parts cloud history marking system, the complete production history from orders, production, quality, and shipping reports, production information can be quickly queried from mobile devices, providing customers with peace of mind services. 3. Production and sales resume can strengthen the recognition of your products in the market, which will be more helpful in establishing a brand and cultivating consumer recognition. 4. Solve manufacturing problems, improve yield, increase production volume, maximize manpower utilization, and effectively reduce production costs. 5. The carbon footprint is implemented at each production operation node, with complete records and seamless connection with international regulatory requirements. Saving benefits 1. Ineffective working hours are reduced, and meetings can be concluded and decisions made quickly. 2. Virtual 24-hour sales service, quick link to customer interaction information. 3. Overtime work is reduced, operating efficiency is improved, and production capacity is increased. 4. After the product is produced, E-reports will be generated immediately. 5. ISO audit responds quickly, providing a number scan to clearly complete the overall work. 6. Integrate report videos, pictures and text to reduce errors in filing work information. 7. Folders, operating standards, hyperlinks, rapid internal education and training and platform information unification.

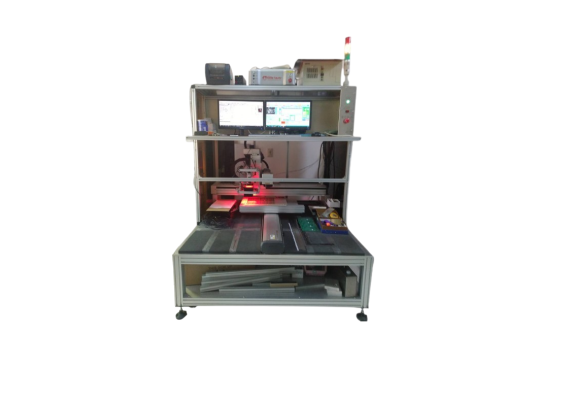

Laser Marking System

Multi-Application Laser Marking System for Multiple Items Our laser marking system is designed for high-efficiency, multi-scene laser engraving needs, making it ideal for factory production, warehouse management, and retail display environments. This system meets various product marking requirements with automatic template switching and position compensation functions, ensuring precise alignment and the quick engraving of clear, unique IDs and barcodes. It uses matrix alignment or reel-to-reel fixture modes and is equipped with a CCD automatic alignment system, significantly boosting productivity and engraving accuracy. Compatible with multiple materials like metal, plastic, and fiberglass, it also allows for full-area engraving without the need for fixtures, adding flexibility and convenience. The content of the markings can dynamically change according to needs, making it suitable for traceability and unique product coding requirements, widely applicable in product specification labeling, material management, and traceability coding. Processing information capture, real-time production data recording, and instant reporting enable managers to monitor production status closely, ensuring consistent, high-quality markings compliant with international verification standards (ISO).

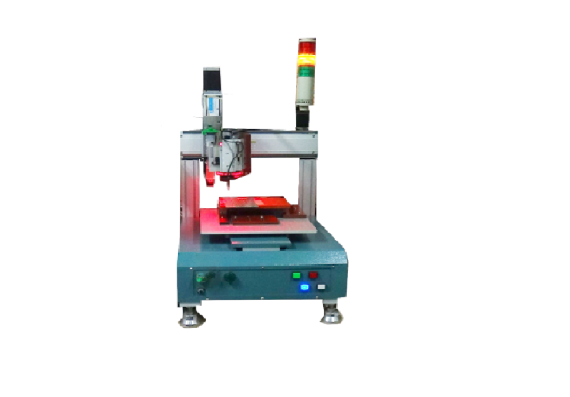

Automatic visual dispensing system

Our fully automated vision-guided dispensing system is specifically designed for multiple-object adhesive dispensing needs. Equipped with vision recognition technology, the system can accurately capture the characteristics of each item, calculate planar coordinates and angular deviations, and dynamically compensate for positional variances to ensure precise adhesive dot placement. This technology effectively corrects deviations between each object and the dispensing nozzle, significantly enhancing process stability. The system is compatible with various material surfaces, including metal, plastic, electronics, glass, and optical components, making it ideal for industries requiring high-precision bonding. Additionally, the system can operate reliably even in environments where jigs are not stably positioned, delivering exceptional reliability and consistency, making it an excellent choice for high-standard bonding applications.

Automatic camera system

This high-efficiency automated machine is specifically designed for multi-object imaging needs. Equipped with vision recognition capabilities, the system accurately captures each item’s features and calculates planar coordinates while dynamically compensating for angular deviations to ensure stable and precise image positioning. The equipment is suitable for industries that require recorded imaging, especially in environments where jigs are not stably positioned, providing highly consistent image data. The system supports automatic path alignment compensation, intuitive CCD teaching, and allows storage of captured images according to preset rules and paths. Additional features include brightness adjustment, distance measurement, array coordinate generation, 1D and 2D barcode scanning, quick order opening, and color photo storage, making it an ideal choice for high-precision imaging applications.

Signal synchronization control card

The Signal Synchronization Control Card is a multifunctional, independent signal control solution offering stable noise filtering and signal shaping output, simplifying camera-to-controller wiring while providing high-speed trigger synchronization, ensuring stable and accurate output. General Problem-Solving features include built-in noise filtering, signal stability shaping, and interface level control conversion, enhancing the reliability of signals. It also features stable timing synchronization and high-speed triggering, ensuring consistent signal output. For special applications, the Signal Synchronization Control Card supports a wide range of voltage inputs(2V~5V、12~24V), provides multi-channel synchronous signals to match the main field frequency(MAX=100KHZ), and triggers area cameras at a high speed of 3500 frames per second to synchronize precisely with the light source controller. The system can be expanded to 64 channels, supporting various external synchronization options, and offers a high level of adaptability to field requirements. In development support, the control card provides a fast setup and verification platform, enhancing the efficiency of designers by allowing rapid setup of structure and electrical control parameters, as well as early system operation verification. It also aids new personnel in gaining practical experience while learning the system. Multi-mode signal output options include I/O card mode, lookup trigger mode, dark/bright field sync mode, sensor level conversion for external synchronization, signal generator mode, RGB light source sync mode, and multi-channel sync control mode, providing users with flexible control options to suit diverse applications.