Company introductionhttps://www.cils.coretronic.com/

Business item(s)

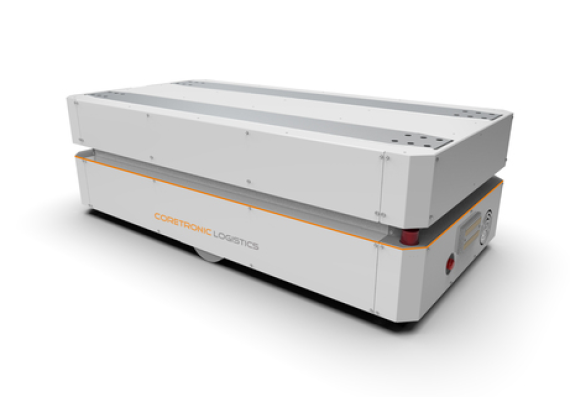

Pallet Lifter (FL-D800L)

In order to solve the difficulties of using the automatic transport system in the dense storage space and enhance the space utilization rate, CKD Intelligent Logistics independently develops the integrated truck with loading platform and fork design, which utilizes the smallest volume to perform the same function as the forklift, and is equipped with the ability of AI pallet recognition to identify the suitable type of goods to be transported, and lifts up the tines to pick up in case of the Chuanzhi pallet, and the lifting platform to top-lift the goods when it meets with the Tienzhi pallet or the material rack, and completes the transport task. In the limited storage space where forklift can not be used, it can also move the palletized goods autonomously, overcoming the restriction that palletized goods need to be moved with the help of huge forklift, and bringing a brand-new breakthrough to the application of AMR. Body Construction. - The top of the truck is designed to be a universal loader that can be adapted to the cargo or pallet type. - Forks embedded in the load table: Recognize the pallet type and make the lifting table or forks. - Forks non-slip design: Forks are made of non-slip material to prevent the pallet from slipping off. - Forks can be matched with pallet type - 25 types of field pallet, 18 types of Kawasaki pallet. Positioning navigation and safety management - Positioning navigation: SLAM navigation, no need to stick magnetic tape, QR Code, complete positioning at once. - Security: Front and rear 2D LiDAR each. - Energy Management System: Li-ion battery autonomous charging≦3.5 hours, continuous operation 5.5 hours. 1. AI Recognition of Pallet Type: The sleigh truck can recognize the pallet type as field type or Sichuan type, and the lifting platform will make corresponding action according to the pallet type. If the pallet is recognized as TianZi type, the fork loader will not lift up to pick up the goods and will directly take over the goods with the flat platform; if the pallet is recognized as ChuanZi type, the fork loader will lift up to pick up the goods. 2. 3D imaging to recognize cargo location information: AMR uses ToF 3D camera stereoscopic image sensing technology to recognize the size, position and depth of the pallet to accurately determine the location of the goods to be picked up. 3. No need for stacker to move palletized goods: The width of the truck is equal to or smaller than the pallet, which means that the palletized goods can be moved in the smallest space to save space. 1. AI Recognition of Pallet Type: The sleigh truck can recognize the pallet type as TianZi or ChuanZi, and the lifting platform will make corresponding action according to the pallet type. If the pallet is recognized as TianZi type, the fork loader will not lift up to pick up the goods, but directly take up the goods with the flat platform; if the pallet is recognized as ChuanZi type, the fork loader will lift up to pick up the goods. 2. 3D imaging to recognize cargo location information: AMR uses ToF 3D camera stereoscopic image sensing technology to recognize the size, position and depth of the pallet to accurately determine the location of the goods to be picked up. 3. No need for stacker to move palletized goods: The width of the truck is equal to or smaller than the pallet, which means that the palletized goods can be moved in the smallest space to save space.

iMEC integrated Management Execution Control System

iMEC intelligent integration management system integrates the complex information flow and hardware equipment in the field into an intuitive management, coordinates the field operation and equipment in series, makes the operation and management simpler and more real-time, provides the optimal resource allocation, connects the information flow, controls the collaboration of multiple equipment, and improves the accuracy and real-time operation through AI-assisted identification, realizing the automation and upgrading of the field. Currently, iMEC has been practically applied in domestic and overseas famous manufacturers, northern computer manufacturing plants, southern famous packaging plants, and supermarket logistics centers. 1. Peripheral equipment connectivity: Seamlessly connecting with customer ERP and MES systems, and implementing AMR task dispatch under VMS system, connecting IT and OT and comprehensively controlling peripheral equipment in the field, such as: automatic doors, conveyors, scanners, elevators, loading machines, realizing a single platform to manage all field equipment, effectively managing multi-vehicle collaboration and giving instructions to handle tasks. 2. Account integration: Integrate information flow and logistics, from process control, material receipt and dispatch to inventory management, all with digital monitoring and control. 3. 3. Real-time remote monitoring: AMR can monitor the progress of task execution through computers or handheld devices (NB/PAD/PDA), and instantly grasp AMR vehicle status (e.g., battery status, maintenance recommendations) and connected equipment. 4. Logistics tracking, warehouse management and control, so that the overall operation is faster and more accurate. AI application integration: AI recognizes the status of storage space and the flatness of palletized goods, detects that the storage space is not occupied and that the palletized goods are flat, and then carries out the warehousing action to enhance the efficiency of transportation and ensure the safety of the goods. 5. Information visualization: Converting information into data charts in real time, information visualization can intuitively monitor and manage the operation process, more quickly and immediately grasp the operation progress, and improve the operation efficiency. 6. Flexible customization: According to the customer's site conditions, we can create the following: moving schedule (push-back racks, continuous stacking), and tactical signage to optimize the use of efficiency by adapting to the needs of the site. 7. User-friendly interface: Provide user-friendly interface according to user's role (FAE/SI/Customer). 8. Moving Efficiency Statistics: Provide the total number of moves and the number of successes on a daily/weekly basis to provide customers with a real-time view of the moving efficiency. 9. Multi-vehicle delivery mechanism: Provide multi-vehicle delivery mechanism for the same site, cross-site, and cross-standard sites to maximize the efficiency of moving.