Company introductionhttp://www.fs-technology.com

Business item(s)

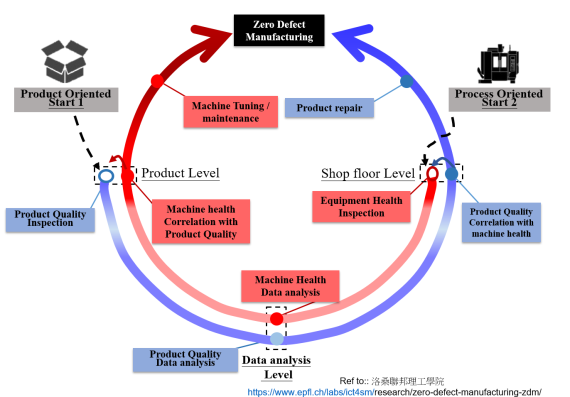

Zero Defect Manufacturing

Safety is Big Issue in Future Auto: BMW manufactures 6000 cars per day Premium vehicles have more than 3500 semiconductors At 1ppm - that is 21 cars parked at the end of the manufacturing line every day 7000 cars a year

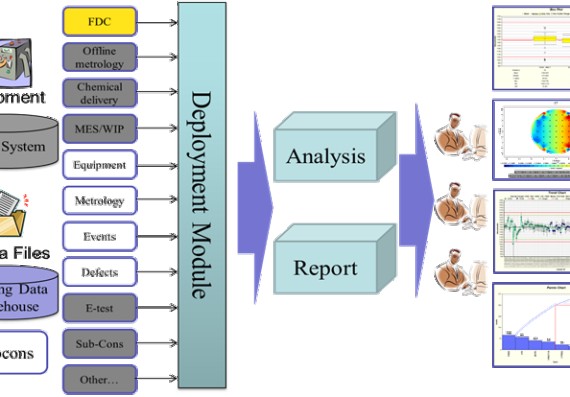

EDA

Engineering Data Analysis (EDA) is an indispensable analysis tool for the engineering team of the industries to analyze processes, integration, and yield (conversion rate) effectively in order to enhance the competitiveness of the company.

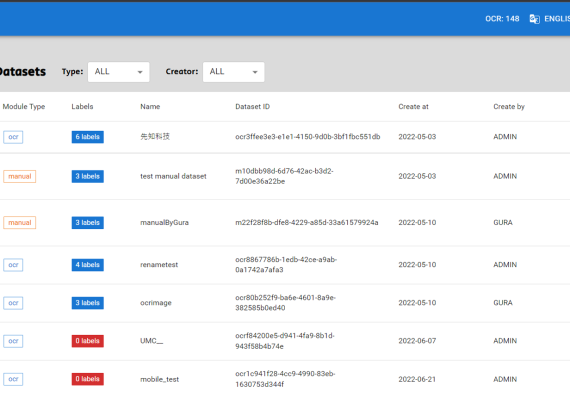

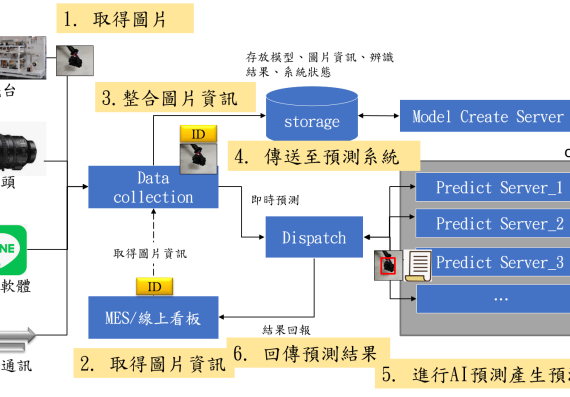

AI天眼通

Electronic wire:Detection & Classification Visual Recognition of Aluminum Wheel: Purpose: Assist the robot arm to avoid mistakenly wheel of the processing line, the robot arm automatically picks out the wrong wheel. Application (Classification) Hot spot identification Purpose: Identify the position of the wheel valve hole to assist the machine to automatically correct the position of the wheel. Application(Position) Specific target recognition

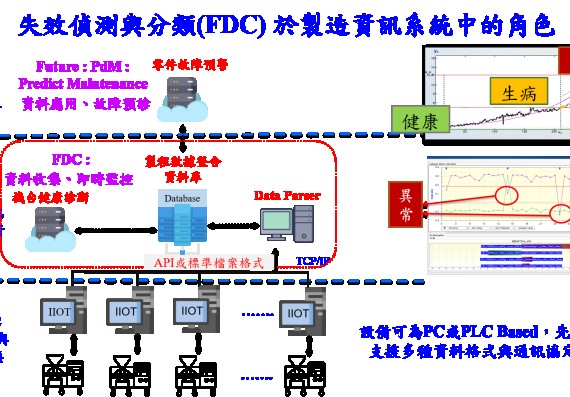

FDC

FDC (Fault Detection and Classification ) Introduction: The systematic method replaces the personnel monitoring the status of the machine in the process, intercepts it in time, avoids a large number of scraps, and conducts difference analysis when an abnormality occurs, allowing users to quickly eliminate the abnormality。