Company introductionhttps://www.zimmer-group.com/en/

Business item(s)

MATCH End-of-Arm-Ecosystem

For Any Robot. Any Gripper. Any End-Effector. This is what we call the new multi-functional end-of-arm platform from Zimmer Group and Schmalz, two technology leaders and handling specialists. Equipped with an extensive range of functions and universal communication interfaces, MATCH is compatible with all common lightweight robots on the market – an ideal system for cobots and conventional 6-axis robots. STANDARDIZATION OF THE ROBOT INTERFACE The MATCH series offers one-of-a-kind standardization potential: The MATCH robot module can be mounted to the most common robot types and acts as the connection for the entire range of MATCH-compatible end effectors. These unified robot connecting flanges offer a high degree of flexibility in the choice of applications. The attached end effectors, whether grippers or suction cups, can easily be replaced manually or automatically using the click system. Standardized and ready-to-connect solutions guarantee maximum system availability. ECOSYSTEM – LARGE SELECTION OF END EFFECTORS The MATCH portfolio includes a large selection of grippers from Zimmer Group. This is not limited to the use of cobots, i.e., human-robot collaborations, but also includes industrial robots. In addition to grippers from Zimmer Group, end effectors with vacuum technology from Schmalz are also compatible with the MATCH system. The MATCH ecosystem is not only made of physical components but also includes various software solutions: A Comfort app coordinated with the specific robot manufacturer enables direct control and monitoring of functions. YOUR BENEFITS [1] A system for lightweight robots, cobots and conventional robots [2] Compatibility & flexibility – combining the primary handling technologies (vacuum and mechanical gripping) [3] Long service life, even in automated continuous operation [4] Innovative digital ecosystem [5] Large variety of end effectors [6] Manual exchange with easy-click function [7] Automated exchange in the device

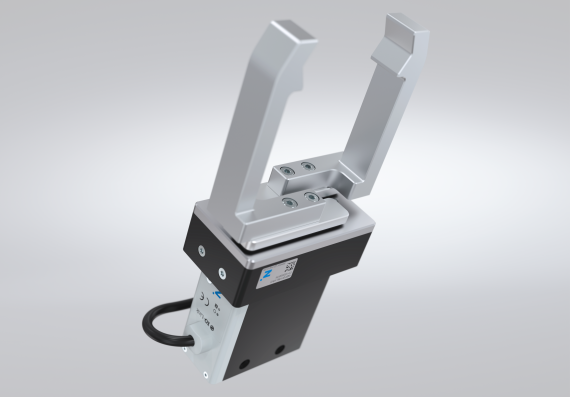

New Series GEP2000- Electric Gripper for Cleanroom

The Zimmer Group is an important partner for individual solutions for numerous companies in the medical, pharmaceutical and packaging sectors. Driven by stringent demands for quality, durability and safety, many of our standard products from various technology areas are able to master these challenges. No matter what product you are handling. TÜV-CERTIFIED Clean rooms are divided into special clean room classes depending on the particle density and emissions. They are subject to strict, standardized requirements and are classified according to the degree of air purity. Clean rooms are divided into classes ISO 1 through 9, where purity class 1 represents the purest because it has the lowest possible particle concentration. After undergoing successful certification processes, over 500 Zimmer Group grippers and clamping elements have been certified according to international standard DIN EN ISO 14644-1 for clean room classes between 2 and 6 thanks to their low particle emissions. The most successful electric small-part grippers of the GEP2000 series are getting a product upgrade with the new protector version. The clean room class 2 certified GEP2000 is ideally suited for use under increased hygiene requirements and in clean rooms thanks to low particle emissions. It comes with wipers on the top cover, the gripper has an enhanced protection class and is thus sealed in accordance with IP54. Because it is lubricated with food-grade H1 grease and equipped with sealed guides, it is an optimal fit for use in the food industry. In addition, it also has optimized corrosion protection and is very easy to clean due to the cover and screws made out of stainless steel. Compared to grippers without a protector, the new version has an enlarged stroke of 10 mm per gripper jaw, which can be increased to 20 mm with other installation sizes.