会社紹介www.ylm.com.tw

業務項目

Automation Work Cell

The YLM Automation Work Cell has outstanding features as below. The Automation Work Cell is 100% designed and manufactured by YLM. The Automation Work Cell can help customers to achieve fully automated production Planning and predicting the production process by 3D simulation software function to get the best production efficiency plan. The fully self-developed central control system creates the application of production lines flexibly. Autonomous detecting for abnormality, which can eliminate defective products automatically and warn the operator for re-inspection.

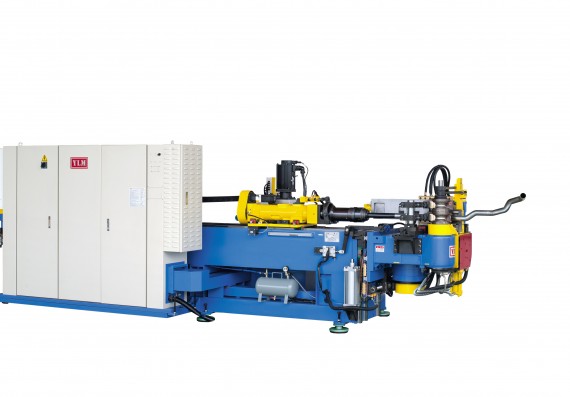

CNC Pipe Bending Machine

YLM CNC bending machines have outstanding features as below. With highly flexible machine design, customized modules can be developed according to customers' special workpieces. Additional functions such as pipe cutting and punching can be added according to customer needs. Several processes can be completed in the same machine to increase work efficiency. With 3D simulation software function, the production process can be planned and predicted to get the best efficient production plan. The hybrid models are equipped with a simple and easy-to-learn PC-BASE controller, humanized control, easy to learn, easy to understand, and easy to operate. Their excellent production performance can meet all applications in various industries. The boosting function can minimize the problem of tube snapping or cracking to achieve the best production efficiency and bending pipe quality.

Cutting Machine

The YLM Cutting Machine has outstanding features as below. Vertical saw blade movement enhances stability and precision. Specialized precision open-style clamps are devised on main clamping and feeding. Strengthened clamping force and adjustable pressure will maintain intact of tube being processed. Equipped with display of cutting length (DR type) and idle stop function when there is no tube in feeder.

Tube End Former

The YLM Tube End Former has outstanding features as below. Suitable for tube end-forming of various metal materials. Tube shrinkage and enlarging process simultaneously to secure high accuracy. Both manual & automatic operations are available and equipped with emergency stop device.