Cosmetic Box Assembly Line

Application Summary

Changing lifestyles and rising demands of skin and sun care products encourage the growth of the cosmetics market. Cosmetic box manufacturers are therefore asked to upgrade their facility and increase production output while minimizing overhead costs.

Solution

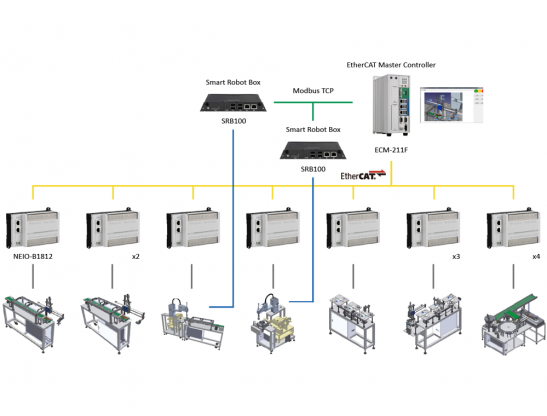

The customer sets a target of assembling 5 cosmetic boxes in one minute, 60 boxes in an hour. A fully automated production line with smart conveyors and robots are deployed to increase manufacturing output and ensure quality control. NexCOBOT provides ECM-211F, an EtherCAT master controller, as the main controller to control up to 19 stations including 2 SCARA robots, 165 digital inputs, and 105 digital outputs.

NexCOBOT develops its own EtherCAT master software that complies with all standard 3rd-party EtherCAT I/O modules. Since the controller efficiently connects and controls all modules in the system, the customer can focus on integrating their cosmetics box production domain know-how to the system.

NexCOBOT also provides SRB100, a smart robot gateway that collects information from robots in the system. SRB100 collects and monitors the robots’ operation mode, status, joint positions, so that the overall process of the assembly line is fully digitalized and displayed on the HMI.

Benefits

● Easy integration: I/O and motor can be easily added/removed via EtherCAT communication

● High productivity: the overall control cycle time is less than 5 seconds

● Shortened development time: shorten the system development by using powerful functions provided in the software utility tool — NexMotion Studio