Company introductionhttps://www.prefactortech.com/

Business item(s)

Visual Components software

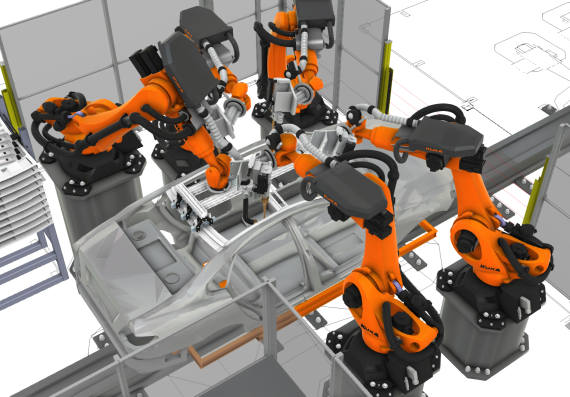

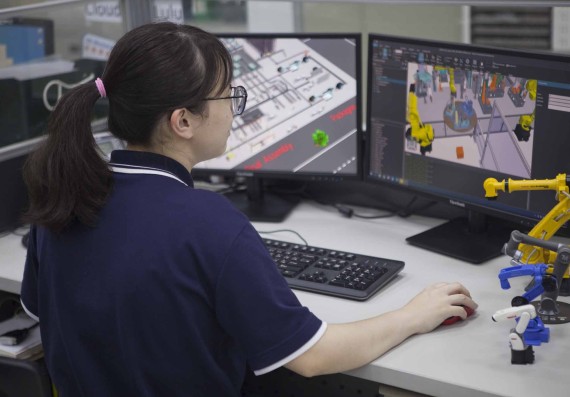

Visual Components: Pioneering a New Era of Digital Twins In today's rapidly evolving manufacturing industry, Visual Components offers a revolutionary solution by integrating digital twin technology with efficient factory planning and design. As the Greater China agent for Visual Components, a Finnish company specializing in simulation software, XianGou Technology leads the forefront of this technology, providing unparalleled solutions for automation systems, robot simulation, logistics simulation, and more. Core Technology and Applications The Visual Components platform boasts an extensive database of 3D models of industrial robots, mechanisms, and logistics systems. These 3D models feature intelligent parameterization, allowing rapid changes in appearance and dimensions, significantly reducing modeling and layout time. This feature is crucial for efficient and precise factory planning and design. Key Efficiency Enhancements Visual Components' plug-and-play functionality greatly enhances the efficiency of robot and logistics simulation. This not only streamlines system layout but also serves as an essential tool for automated design and process planning. Additionally, Visual Components integrates PLC and robot simulation functions, supporting offline programming and enabling efficient connection and integration with physical equipment and factories. Visual Components & NVIDIA Omniverse The integration of Visual Components with NVIDIA Omniverse demonstrates how to utilize virtual environment simulation for efficient factory planning and design. This combination not only provides possibilities for material and multi-user collaboration but also sets new standards for the simulation of robots and unmanned transport vehicles.

Simulation service

PrefactorTech offers manufacturing project simulation services utilizing Visual Components (Digital Twin) for simulation. This includes mechanism analysis, logistics simulation, personnel operations, robot systems, and more. Upon completion of the simulation, XianGou provides comprehensive analysis reports to maximize clients' decision-making efficiency, thereby enhancing productivity. Below are simulation case studies from several well-known enterprises.

Faucet assembly

The components and styles of faucet assembly are complex, with various quality issues such as tolerances and tight-fitting assembly. Additionally, a large amount of manpower is required for assembly operations, prompting the need for automation to address this issue. Prefactor Tech conducts product research for faucet assembly, thoroughly reviewing assembly sequences and quality priorities in collaboration with the client. After confirmation through experimentation and digital simulation planning, Prefactor Tech completes the design, manufacturing, adjustment, and mass production of a diverse automated assembly line. This system includes units such as conveyor belts, feeding towers, vibrating trays, multi-axis robots, visual systems, servo-mechanisms, grippers, clamping fixtures, screw-locking machines, pressing units, and more. Through collaboration research and development with the client, Prefactor Tech successfully delivers the automated assembly system for faucet components.

Cutter holder assembly

The cutter holder comprises numerous components, and in the past, assembly, and adjustment were manually performed. However, due to differences between peak and off-peak seasons, the allocation of assembly manpower often leads to idle time. Prefactor Tech conducts product research for cutter holders, thoroughly reviewing assembly sequences and quality priorities in collaboration with the client. After confirmation through digital simulation planning, and following design, manufacturing, and adjustment phases, Prefactor Tech completes the automated assembly system for cutter holders. This system includes units such as conveyor belts, multi-axis robots, servo mechanisms, grippers, clamping fixtures, screw-locking machines, riveting machines, pressing units, and more. Through system integration and collaboration with the client, Prefactor Tech successfully delivers the automated assembly system for cutter holders.

Automation for Hinge assembly

Although there aren’t many parts in a hook assembly, quality issues such as tight-fitting assembling are raised often. A large quantity of workforces is needed for the assembling process. We are looking forward to solving this problem by automating our devices. Prefactortech completes the design, manufacturing, adjustment, and mass-production of the automatic hook assembly line by conducting research on hook products, fully reviewing the quality and order of the assembling with business owners, and performing experiments and digital simulations to confirm the design. The system includes material barrels, vibration plate, multi-axis robots, vision systems, servo-mechanisms, grippers, fixtures, screw locking machines, riveting machines, push-in machines, etc. Through development corporations with business owners, we are able to complete the automatic hook assembling system.